Menene extrusion aluminum?

Aluminum extrusion wata dabara ce da ake amfani da ita don canza alloy na aluminium zuwa abubuwa tare da madaidaicin bayanan ɓangaren giciye don fa'idodin amfani.Shi ne mafi mashahuri yanayin sarrafawa don aluminium.

Biyu daban-daban extrusion dabaru

Akwai dabaru guda biyu daban-daban na extrusion: extrusion kai tsaye da extrusion kai tsaye.

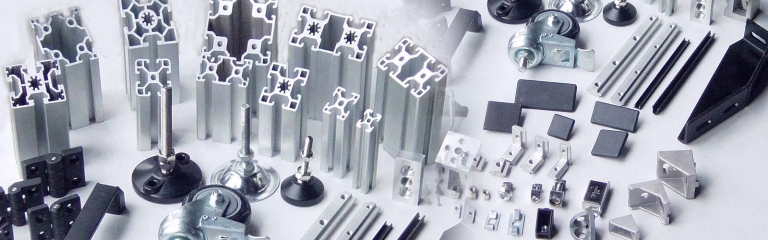

Wadanne nau'ikan siffofi ne za a iya fitar da su?

● Siffai mara kyau: siffofi kamar bututu ko bayanan martaba tare da sassa daban-daban na giciye

● Siffofin da ba su da ƙarfi: irin waɗannan siffofi sun haɗa da tashoshi, kusurwoyi, da sauran sifofi da aka buɗe.

● Siffai masu ƙarfi: Wannan ya haɗa da sanduna masu ƙarfi da sanduna tare da sassan giciye daban-daban.

● Siffofin Extrusion Aluminum na al'ada: Waɗannan nau'ikan sifofi yawanci suna da extrusions da yawa.Hakanan, suna iya zama sifofi masu haɗaka tare da bayanan martaba masu launi da yawa.Waɗannan sifofi daidai suke da ƙayyadaddun masu ƙirƙira.

Matakai 6 na Fitar Aluminum

● Ana aiwatar da tsarin extrusion a cikin matsi na extrusion tare da matakan iko daban-daban.Ana iya raba ainihin tsari zuwa matakai daban-daban guda shida.

● Kuma kafin aikin extrusion ya fara, simintin gyaran gyare-gyare na aluminum yana buƙatar yanke zuwa guntu guntu.Wannan yana tabbatar da tsawon kowane mashaya da aka fitar zai zama kusan iri ɗaya kuma ya guji ɓarna kayan.

Mataki 1: Dumama billet na aluminum da karfe mutu

Ana ɗora billet ɗin daga zafin ɗaki zuwa extrusion Yanayin zafin jiki ya bambanta dangane da gami da zafin ƙarshe.

● Don hana asarar zafi, ana ɗaukar billet ɗin da sauri daga tanderun zuwa cikin latsawa.

Mataki 2: Load da billet a cikin kwandon latsa extrusion

● Ana ɗora kayan simintin gyare-gyare a cikin akwati kuma a shirye suke don fitar da su.

● Ragon ya fara matsa lamba a cikin billet ɗin mai zafi sannan ya tura shi zuwa wurin buɗewa.

Mataki na 3: Extrusion

● Ana tura billet ɗin aluminum mai zafi ta hanyar buɗewa a cikin kayan aiki.Ana iya canza waɗancan buɗewar don ƙirƙirar bayanan martaba na Aluminum tare da siffofi da girma dabam dabam.

● Lokacin da sanduna suka fita daga latsa, an riga an fitar da su cikin siffar da ake buƙata.

Mataki na 4: Sanyi

● Tsarin extrusion yana biye da saurin sanyaya na sanduna / tubes / bayanin martaba

● Don hana kowane nakasawa, dole ne a aiwatar da tsarin sanyaya nan da nan bayan aikin extrusion.

Mataki na 5: Miqewa da Yanke

● Nan da nan bayan quenching, an yanke sandunan da aka fitar a cikin tsayin tsaka-tsakin da aka kayyade. Sai a kama sandunan da mai jan wuta, wanda ya shimfiɗa su a kan teburin gudu.

● A wannan mataki, sandunan extruded suna zuwa tsarin ƙarfafawa, yana tabbatar da kayan aikin injiniya ta hanyar cire tashin hankali na ciki a cikin sanduna.

● An yanke sanduna zuwa tsawon da abokin ciniki ya nema.

Mataki na 6: Jiyya na saman ƙasa da marufi na ƙarshe

● Ana yin jiyya na saman akan bayanan martaba na aluminum, kamar anodizing, spraying, da dai sauransu, don haɓaka aikinsu da bayyanar su.

● The extruded sanduna / tubes / profile zama cushe da kuma shirye don kaya.

Amfanin Aluminum extrusion:

Ɗayan sanannen ci gaba a fasahar extrusion aluminum shine ikon samar da bayanan da aka yanke zuwa tsayi.Wannan tsari ya ƙunshi extruding aluminum profiles a cikin takamaiman tsawo, kawar da bukatar kara yankan ko machining.Amfanin bayanan bayanan da aka yanke zuwa tsayi suna da yawa:

● Rage Sharar gida: Tare da bayanan bayanan da aka yanke zuwa tsayi, masana'antun na iya rage sharar kayan abu ta hanyar samar da bayanan martaba waɗanda aka keɓance da tsayin da ake buƙata, don haka inganta amfani da kayan da rage farashi.

● Ƙarfafa Ƙarfafawa: Ta hanyar kera bayanan martaba a cikin madaidaicin tsayi, yanke-zuwa-tsawon extrusion yana tabbatar da daidaito da daidaitattun ma'auni, inganta haɗuwa maras kyau da kuma rage kuskuren kuskure.

● Ƙirƙirar Ƙarfafawa: Bayanan da aka yanke zuwa tsayin daka yana da mahimmanci wajen sauƙaƙe tsarin masana'antu yayin da suke kawar da buƙatar ƙarin aikin yankewa ko machining, adana lokaci da inganta ingantaccen aiki.

Lokacin aikawa: Dec-18-2023